Archives

ACT

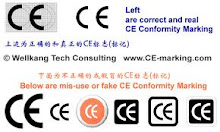

Council Decision 93/465/EEC of 22 July 1993 concerning the modules for the various phases of the conformity assessment procedures and the rules for the affixing and use of the CE conformity marking, which are intended to be used in the technical harmonisation Directives.

SUMMARY

This Decision establishes a range of procedures for assessing the conformity of industrial products to the "essential requirements" laid down by the technical harmonisation Directives. It aims to protect public interests such as the health and safety of product users.

Conformity

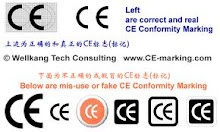

The CE marking symbolizes the conformity of a product to the Community requirements incumbent on the manufacturer of the product. It indicates that the product conforms with all the Community provisions providing for its affixing.

Member States may not restrict the placing on the market and entry into service of products bearing the CE marking, unless there is supporting evidence of the product’s non-conformity. The marking should be affixed prior to the product being placed on the European market and entering into service.

Scope

The Decision lays down rules for affixing the CE conformity marking concerning the design, manufacture, placing on the market and entry into service of a product.

CE marking can be introduced in Community legislation as conformity marking if:

- a directive is in accordance with the principles of the new approach and the global approach;

- the method of total harmonisation is used;

- the directive contains conformity assessment procedures in accordance with this Decision.

Declaration of conformity

Directives may exclude the affixing of the CE marking on certain products. These products may circulate freely on the European market if they are accompanied by, for example, a declaration or certificate of conformity.

Responsibility of manufacturers

The CE marking must be affixed by the manufacturer or his agent established within the Community. The manufacturer bears ultimate responsibility for the conformity of the product.

Conformity assessment relates to the design and production phases of the product. Depending on the conformity assessment procedures applied, a notified body may be involved in these two phases. If the notified body is involved in the production control phase, its identification number will follow the CE marking.

If a product falls within the scope of a directive that provides for the CE marking, this should be affixed:

- to all new products, whether manufactured in the Member States or in third countries;

- to used and second hand products imported from third countries.

Assessment modules

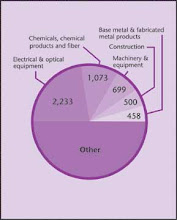

The decision provides for eight assessment procedures or "modules" which cover the design and production phases:

- internal production control (module A);

- CE type-examination (module B);

- conformity to type (module C);

- production quality assurance (module D);

- product quality assurance (module E);

- product verification (module F);

- unit verification (module G);

- full quality assurance (module H).

Context

Decision 93/465/EEC is repealed by Decision No 768/2008/EC  on a common framework for the marketing of products. The provisions relating to EC marking.

on a common framework for the marketing of products. The provisions relating to EC marking.

REFERENCES

| Act | Entry into force | Deadline for transposition in the Member States | Official Journal |

| Decision 93/465/EEC [procedure COM/93/144-02] | 22.07.1993 | - | OJ L 220 of 30.08.1993 |

RELATED ACTS

THE "NEW APPROACH"

Council Resolution of 10 November 2003 on the Communication of the European Commission "Enhancing the Implementation of the New Approach Directives" [Official Journal C 282 of 25.11.2003].

Communication from the Commission of 7 May 2003 to the Council and the European Parliament "Enhancing the implementation of the New Approach Directives" [COM(2003) 240 final - Not published in the Official Journal].

In order to give fresh impetus to the technical harmonisation system, this Communication recommends better ways to implement the New Approach Directives.

Directive 98/34/EC of the European Parliament and of the Council of 22 June 1998 laying down a procedure for the provision of information in the field of technical standards and regulations and regulations on information society services [Official Journal L 204 of 21.07.1998].

This Directive aims to eliminate or reduce the barriers to the free movement of goods that can arise from the adoption of different national technical regulations.

Council Resolution of 21 December 1989 on a global approach to conformity assessment [Official Journal C 10 of 16.01.1990].

Council Resolution of 7 May 1985 on a new approach to technical harmonization and standards [Official Journal C 136 of 04.06.1985].

PRODUCT SAFETY

Directive 2001/95/EC of the European Parliament and of the Council of 3 December 2001 on general product safety [Official Journal L 11 of 15.01.2002].

The general safety of products placed on the market is guaranteed by Community legislation, which ensures a consistent, high level of protection for the health and safety of consumers.

Council Regulation (EEC) No 339/93 of 8 February 1993 on checks for conformity with the rules on product safety in the case of products imported from third countries [Official Journal L 40 of 17.02.1993].

Last updated: 27.11.2008

See also

Further information is available on the website of the European Commission’s Enterprise and IndustryDirectorate-General.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)