Monday, March 1, 2010

IS 2148: 2004 is OBSOLETE now

The Bureau of Indian Standards- An overview of its evolution and relevance. The history of BIS dates back to the pre-independence era. During this period standardization activity was largely sporadic & was confined to a few government purchasing organizations.However post independence, economic development through coordinated utilization of resources was called for and government recognized the role of standardization in gearing the industry to efficiency and quality production. In view of this ISI was set us in 1947 as a registered society under Government of India resolution. Post independence and with the gradual liberalization of the Indian economy saw a spurt in economic / technical activities in India. Government recognized the need to strengthen the National Standards Body and thus came the formation of BIS.

The main objectives of BIS are-

Harmonious development of standardization, marking and quality certification

To provide new thrust to standardization and quality control

To evolve a national strategy for according recognition to standards and integrating them with growth and development of production and exports

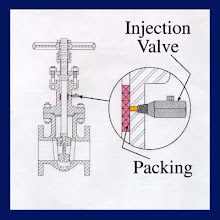

BIS in the context of Ex Industry-BIS, is the national code laying body for Electrical Equipment in Potentially Hazardous Locations. They are instrumental in setting the guidelines / standards in the areas of Equipment Construction & testing, Area Classification, selection, installation and maintenance of Ex Equipments.

On recommendation of the Electro technical Division Council, BIS has aligned IS standards with IEC standards. Some of the important / prominent standards which have been harmonized are-

IS/IEC

Enacted In

Superseding / Corrosponding to Earlier

IS / IEC 60079 – 0 : 2004

October, 2007

IS 13346:2004.

IS / IEC 60079 – 1 : 2007

December, 2007

IS 2148: 2004

IS / IEC 60079 – 7 : 2001

June, 2004

IS 6381:2004

IS / IEC 60079 – 11 : 2006.

September, 2008

IS 5780: 2002

IS/IEC 60079-15: 2005

October, 2008

IS 8289:1976

IS/IEC 60079-18: 2004

September, 2007

IS 15451:2004

IS/IEC 60079-19: 2006

July, 2008

NA

Although, the BIS scheme itself is voluntary in nature, The Petrolum Explosive Safety Organisation, PESO has enforced a mandatory requirement for Indian Manufactureres towards BIS certification (as per IS/IEC 60079~O:2004& IS 2J48:2004/IEC 60079.1:2007) on products (conforming to flameproof Ex "d" protection concept)

Karandikar Laboratories is India’s first private sector laboratory which is recognized by the BIS for performing the tests in the process of product certification.

Your search for a BIS approved test laboratory for for - Electrical Apparatus for explosive gas atmospheres - flameproof enclosures 'd' as per IS 2148 is over.

To get your products tested call us at 91-022-28471395/96/97. You can also write to us at sales@karandikarlab.comPetroleum Explosive Safety Organization- PESO

The objective of PESO is to regulate and monitor the manufacture, import, export, transport, possession, sale and use of explosives, petroleum products and compressed gases as envisaged under the Explosives Act 1884 and Petroleum Act 1934.

PESO is currently involved in regulation of over 2,56,000 premises all over India. The approval of chief controller of explosive CCoE is mandatory for all electrical equipment installed in potentially explosive atmospheres

Rule 106 of Petroleum Rules prescribes that all equipment operating on electrical energy are required to be approved by Chief Controller of Explosives if they find application in hazardous areas falling within the purview of Petroleum Rules, 2002. The approval of electrical equipment is therefore limited to only such areas falling within the jurisdiction of Petroleum & Explosives Safety Organisation

Chief Controller of Explosives permits use of flameproof, intrinsic safety and encapsulated type protected equipment for use in zone 1 hazardous areas. Non sparking and increased safety type equipment are permitted in zone 2 hazardous areas.

The test certificate issued by Karandikar laboratories enables a manufacturer to obtain approval from CCoE

We enable the manufacturer by to understand-

Technical details of the equipment including engineering drawings.

Understanding the requirements of the standards.

Evolving a test program based on the above.

Perform the test in line with the requirement.

If substantiated by the above issue test reports.

Each of these endorsements / approvals involves independent third party assessment against recognised standards. They give further confidence to Manufacturers, Equipment Users and Regulatory Authorities within the area that we operate by demonstrating our competence, impartiality, performance and over 300 years of collective experience resulting from a strong technical tie-up with Baseefa UK.

Your search for a PESO approved test laboratory for for - Electrical Apparatus for explosive gas atmospheres - is over.

To get your products tested call us at 91-022-28471395/96/97. You can also write to us at sales@karandikarlab.com

Home Training Service Facility Certification Contact Us Accreditation

SOURCE

The main objectives of BIS are-

Harmonious development of standardization, marking and quality certification

To provide new thrust to standardization and quality control

To evolve a national strategy for according recognition to standards and integrating them with growth and development of production and exports

BIS in the context of Ex Industry-BIS, is the national code laying body for Electrical Equipment in Potentially Hazardous Locations. They are instrumental in setting the guidelines / standards in the areas of Equipment Construction & testing, Area Classification, selection, installation and maintenance of Ex Equipments.

On recommendation of the Electro technical Division Council, BIS has aligned IS standards with IEC standards. Some of the important / prominent standards which have been harmonized are-

IS/IEC

Enacted In

Superseding / Corrosponding to Earlier

IS / IEC 60079 – 0 : 2004

October, 2007

IS 13346:2004.

IS / IEC 60079 – 1 : 2007

December, 2007

IS 2148: 2004

IS / IEC 60079 – 7 : 2001

June, 2004

IS 6381:2004

IS / IEC 60079 – 11 : 2006.

September, 2008

IS 5780: 2002

IS/IEC 60079-15: 2005

October, 2008

IS 8289:1976

IS/IEC 60079-18: 2004

September, 2007

IS 15451:2004

IS/IEC 60079-19: 2006

July, 2008

NA

Although, the BIS scheme itself is voluntary in nature, The Petrolum Explosive Safety Organisation, PESO has enforced a mandatory requirement for Indian Manufactureres towards BIS certification (as per IS/IEC 60079~O:2004& IS 2J48:2004/IEC 60079.1:2007) on products (conforming to flameproof Ex "d" protection concept)

Karandikar Laboratories is India’s first private sector laboratory which is recognized by the BIS for performing the tests in the process of product certification.

Your search for a BIS approved test laboratory for for - Electrical Apparatus for explosive gas atmospheres - flameproof enclosures 'd' as per IS 2148 is over.

To get your products tested call us at 91-022-28471395/96/97. You can also write to us at sales@karandikarlab.comPetroleum Explosive Safety Organization- PESO

The objective of PESO is to regulate and monitor the manufacture, import, export, transport, possession, sale and use of explosives, petroleum products and compressed gases as envisaged under the Explosives Act 1884 and Petroleum Act 1934.

PESO is currently involved in regulation of over 2,56,000 premises all over India. The approval of chief controller of explosive CCoE is mandatory for all electrical equipment installed in potentially explosive atmospheres

Rule 106 of Petroleum Rules prescribes that all equipment operating on electrical energy are required to be approved by Chief Controller of Explosives if they find application in hazardous areas falling within the purview of Petroleum Rules, 2002. The approval of electrical equipment is therefore limited to only such areas falling within the jurisdiction of Petroleum & Explosives Safety Organisation

Chief Controller of Explosives permits use of flameproof, intrinsic safety and encapsulated type protected equipment for use in zone 1 hazardous areas. Non sparking and increased safety type equipment are permitted in zone 2 hazardous areas.

The test certificate issued by Karandikar laboratories enables a manufacturer to obtain approval from CCoE

We enable the manufacturer by to understand-

Technical details of the equipment including engineering drawings.

Understanding the requirements of the standards.

Evolving a test program based on the above.

Perform the test in line with the requirement.

If substantiated by the above issue test reports.

Each of these endorsements / approvals involves independent third party assessment against recognised standards. They give further confidence to Manufacturers, Equipment Users and Regulatory Authorities within the area that we operate by demonstrating our competence, impartiality, performance and over 300 years of collective experience resulting from a strong technical tie-up with Baseefa UK.

Your search for a PESO approved test laboratory for for - Electrical Apparatus for explosive gas atmospheres - is over.

To get your products tested call us at 91-022-28471395/96/97. You can also write to us at sales@karandikarlab.com

Home Training Service Facility Certification Contact Us Accreditation

SOURCE

Subscribe to:

Post Comments (Atom)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

No comments:

Post a Comment